Bellofram Elastomers brings together two legendary names, Bellofram Diaphragm and Bellofram Silicones

BELLOFRAM SILICONES INC. CAPABILITIES

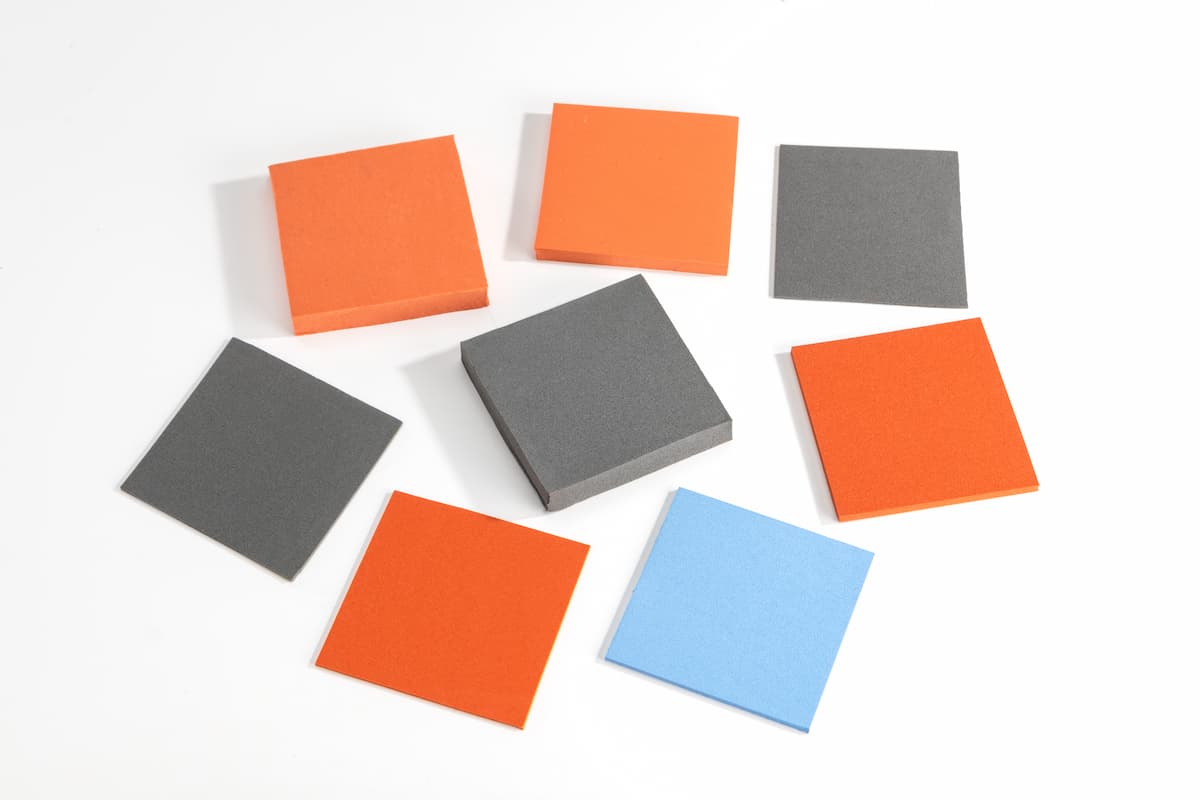

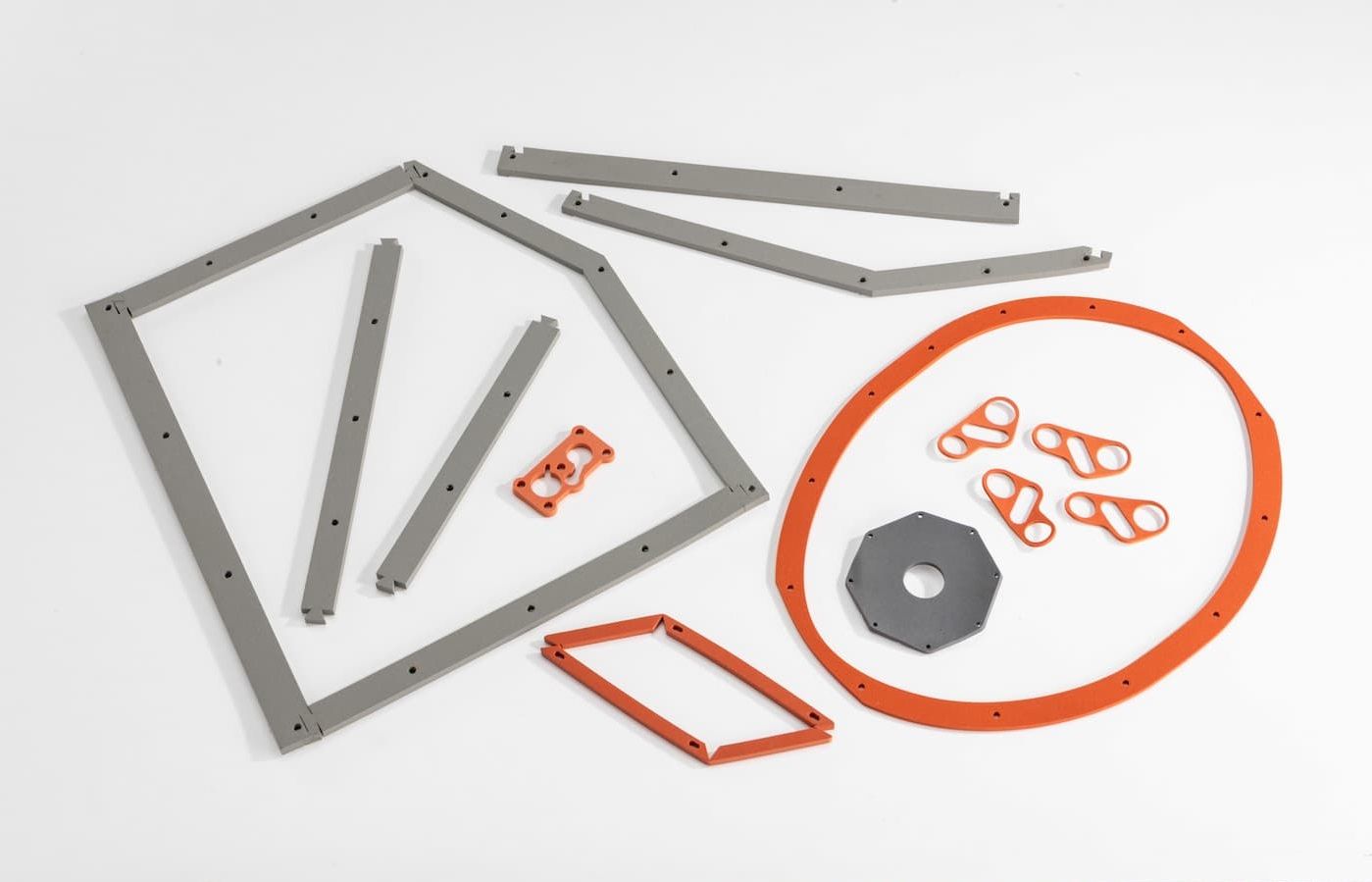

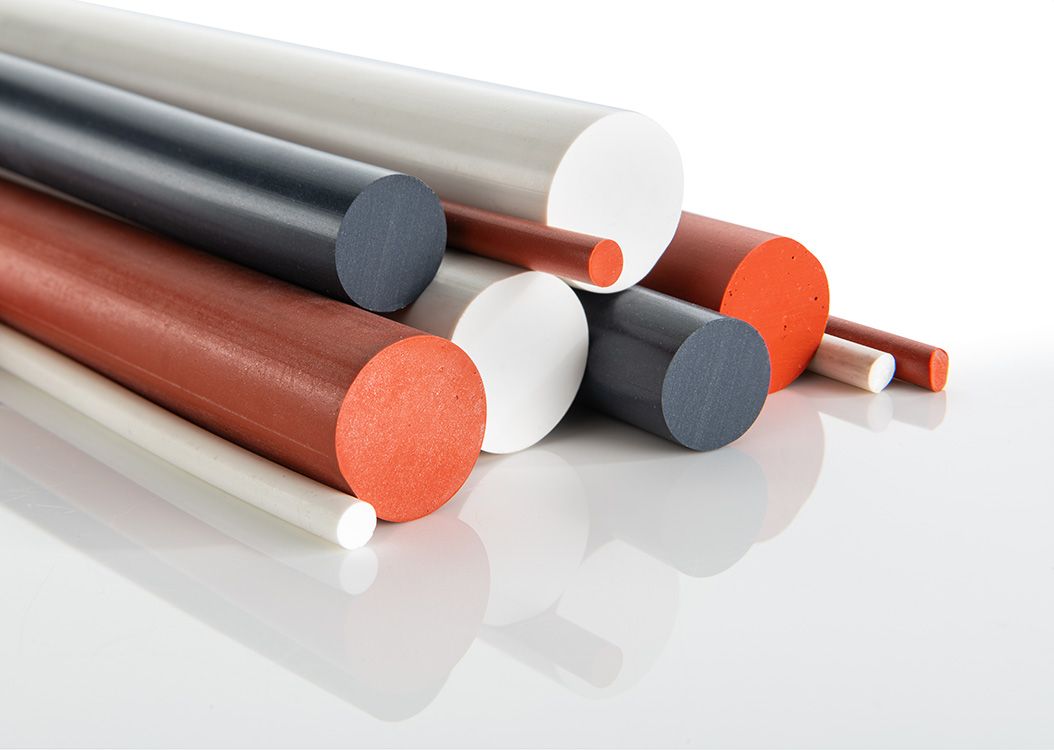

We're a worldwide leader in the manufacture of silicone sponge, rubber sponge, solid silicone, and solid rubber products. We offer an endless variety of extruded profiles, custom molded parts, die-cut parts, and a wide range of flat sheet products for all of your conversion needs.